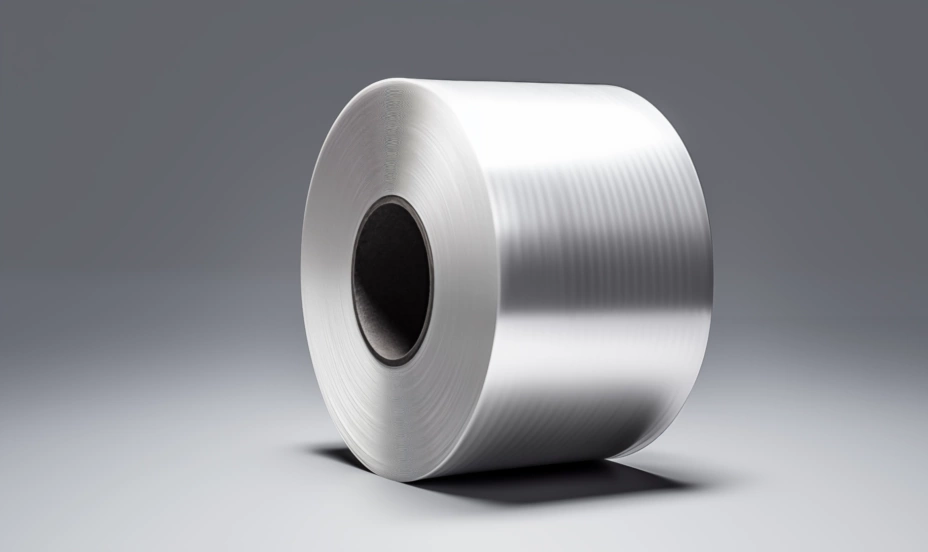

Our state-of-the-art separator film technology ensures a safe and reliable flow of energy in any lithium-ion battery, powering most things that matter. From day-to-day appliances – be it a laptop, smartwatch, scooter or the smartphone you can’t live without – to batteries enabling the electrification of transport or storing intermittent renewable energy.

The separator film is a key component in a lithium-ion battery. It insulates the battery’s anode and cathode from each other and prevents short circuits and overheating while still allowing the ions to be transported between the electrodes. The quality and design of the separator affects the battery’s capacity, life cycle – and not least its safety.

We pride ourselves in being an enabler of electrification. Producing the finest film, making all the difference.