Innovation is one of our strongest motivators. We are passionate about enabling next-generation lithium-ion batteries. Our cutting-edge technology ensures a safe and reliable flow of energy in the batteries that power most things that matter. From day-to-day appliances — be it a laptop, smartwatch, scooter or the smartphone you can’t live without — to the ground-breaking solutions electrifying the entire transport sector and enabling intermittent energy storage. We work closely with our customers to create new solutions, processes, and materials, pushing boundaries within battery lifetime, safety, and reliability.

Innovation

Driven by innovation

Since the beginning of the battery boom, Asian researchers and companies have held a leading position in the development of technologies for an electrified future.

In this, Shenzhen-based Senior Group has played a fundamental role, constantly raising the bar for key battery components. Boasting over 500 patents, Senior Group has established itself as the technological leader in separator film development. As well as one of the world’s largest manufacturers. Today, Senior Group’s separator films are used in more than 5 million vehicles produced annually.

Powering

the future

European R&D Center

We are committed to building a strong local base, where our expertise and technological know-how can provide the finest separator film to a fast-growing list of European and global battery manufacturers.

We have established a new technology center at our plant in Eskilstuna, where we will cooperate with other institutions and universities. This center will allow us to be involved in the development of the European battery value chain together with our customers and suppliers. We will build a research center with upstream and downstream resources in the industry, focusing on new energy, new materials, intelligent manufacturing, green energy, and environmental protection — with the ultimate goal of increasing our resource efficiency, reducing our carbon footprint and always delivering the finest separator film.

Hypermodern factory

Our Eskilstuna facility is under construction and will be fully operational by 2025. Our hypermodern factories will employ more than 600 people and feature the most effective production line for separator film in the world. The factory will be able to produce more than 600 million square meters of separator film per year, enabling manufacturing of 600,000 EV batteries.

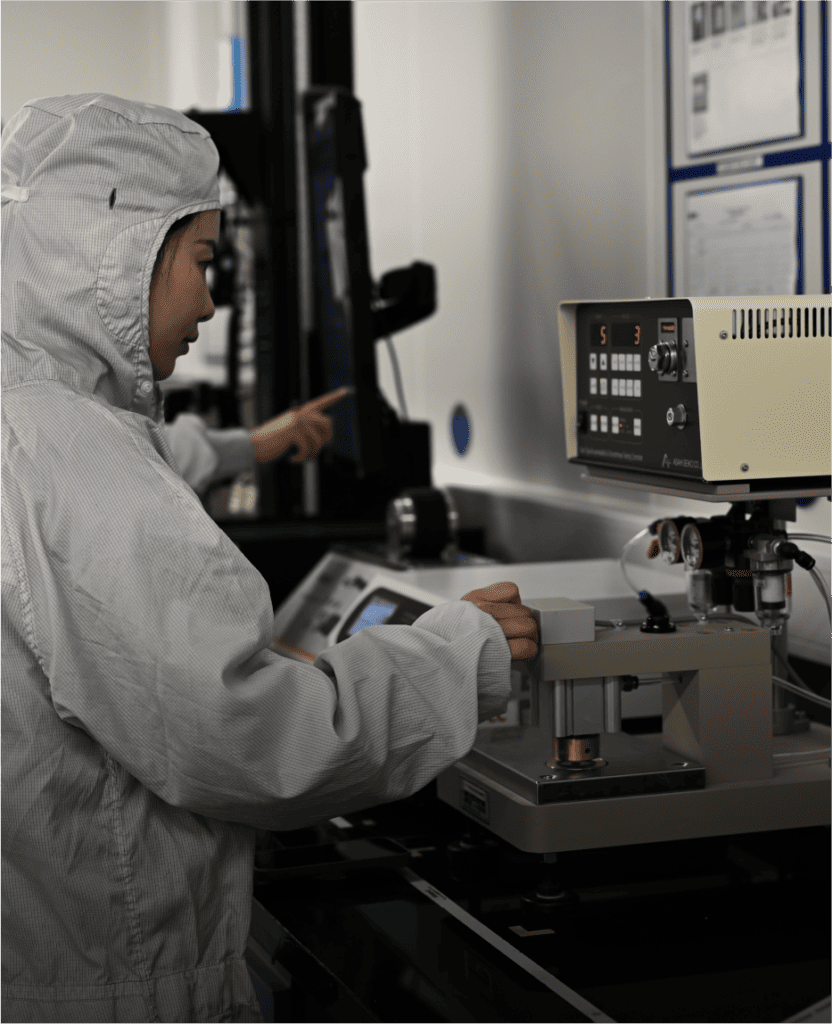

High-quality clean tech production

Automated production lines for coating and slitting separator film are already operational in the first section of our Eskilstuna factory. Like many other industries, clean production conditions are critical in battery manufacturing. Preparation of the slurry (the mixture used to coat the separator film), the coating process, and the slitting of the coated separator film all take place in clean rooms that resemble laboratories rather than an industrial environment. The right temperature, air humidity, and a particle-free environment ensures that the separator film holds the required qualities to guarantee a safe and efficient flow of energy in lithium-ion batteries.